WARNING! Unless you are building a boat or have a lot of time to waste, please move on to the next post.

You are still here? Don’t say I didn’t warn you.

If you have read any of our other posts, you already know that Two Fish is a bit luxurious. Some might even say that it is our American life on two hulls. It may surprise you that we didn’t set out to recreate all of our luxuries on the water, it just sort of happened that way. In fact, we really have tried not to do that. Case in point was the icemaker. While we said yes to the options of Air-Conditioning (If you don’t choose A/C, you don’t get heat either) and to the Washing Machine (we aren’t really counting on it working forever), we drew the line at the built-in ice maker. Ice makers are notoriously hard to maintain and expensive so we decided that we would just buy a inexpensive portable ice maker at Target and use it once in a while.

Enter the NewAir AI-100R Countertop Portable Ice Maker. Advertised as able to make up to 28 pounds of ice per day, it seemed like a dream. Forget the fact that when we bought it, I didn’t really know what 28 pounds of ice really was. (Now I know that the bag you buy at stores is 10 pounds). The biggest calculation that I missed was that since these run off of 120V power, the most we would get in a day would be 90 minutes or 1.75 pounds. Chew on that.

Maybe I have given away the punchline. I eagerly plugged it in and awaited my first cubes of ice.

Pretty dismal. I waited a bit longer and it looked a little more promising but it still didn’t seem like a lot. I reported back to Jason that I wasn’t really sure whether this icemaker thing was going to work out. He wanted more specifics. “Why don’t you be scientific about it?”, was his comment.

So, I set out to follow his advice – there is a first time for everything in this world.

Starting time was 1:31pm on Tuesday, September 25. I plugged in the ice maker. The first 9 cubes were produced at 1:42.

The ice maker timing was very regular. Every 11 minutes, another 9 cubes were deposited in the tray.

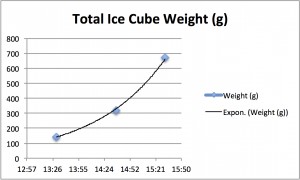

I weighed the 27 cubes at 2:04. They weighed 144 grams.

Question: “What does a refrigerator tray of ice weigh?”

Answer: “16 cubes = 467 grams”.

Next Question: “How long will it take to reach that weight with the ice maker?”

Answer: “Approximately 99 minutes, or, one day’s worth of generator time.”.

In fact, after running the ice maker for 2 hours, I reached a total weight of 672 grams. The other interesting empirical data is that the ice maker became more efficient as time elapsed. Our first 27 cubes weighed 144 grams, the next 9 weighted 175 grams. By restarting it each time we produced cubes, we would be running it at its most inefficient point.

A tray of ice in our freezer (0 degrees) takes about 3 hours to form. Our freezer on the boat would be on most of the time. I decided that 2 trays of ice would be a better strategy. I packed up the ice maker and sent it back.

My advice. Try the ice tray. Don’t fool yourself by looking for a better portable. They all look the same even if they have a different brand name. Somewhere out in manufacturingville, they are producing these and sticking different brand names on the same machine.

Plus, if we all start making our own ice, what will happen to the Marina iceman?