Astute readers will remember Two Fish’s dramatic propulsion problem: while motoring she could only travel in reverse. In an old Car Talk episode, a caller had a car that only could turn right. The caller gleefully announced that she just would use four left hand turns to go right. Gail was quick to announce that Two Fish would not be traveling the Atlantic Ocean in reverse.

After anchoring, we tried to diagnose the problem. We tested whether the engines were shifting. While moving the shifter at the helm, we could see the lever near the transmission moving correctly (little arm moving aft is forward gear). Next we made sure that the shafts were rotating – again a passing grade (forward gear is when the shaft rotates clockwise when the observer is looking forward). So it seemed logical that the Max Props were not operating correctly.

The poor visibility in the muddy waters of the Connecticut River prevented my diving the boat to examine the props and forced us to haul her out of the water. Once again, I was surprised by Gail’s organizational skills. Two minutes after we decided to haul out Gail said, “Jason, a half mile up river is Essex Boat Works and they are one of the few places with a travel lift wide enough for Two Fish. I will book a haul out for the morning.” How did she know that?

The next morning, Sea Tow (AAA for boats) came to help us into a narrow chute leading to the travel hoist. Even with working engines, narrow chutes raise my heart rate faster than a treadmill. What will it be like without engines? Our luck continued as Sea Tow arrived just at slack tide in light winds. Sea Tow did a side tie and acted as my motor. I was steering Two Fish and asking for more or less power from the Sea Tow captain. This was a great time to learn this type of maneuvering. Since the Sea Tow vessel was low to the water, the captain’s view was obscured by Two Fish’s high decks. Near the mouth of the chute I asked Sea Tow to cast off. We then coasted in with the help of half of the boat yard staff. It was easy because of the kind tide and weather. Our luck would not continue.

When we returned to the boat yard, we were greeted by some bad news. The haul-out strap had hooked the propellor and bent the strut. (Brief intro to engines: The engine turns the transmission that then turns the shaft. The shaft then exits the hull and is supported underwater by a strut.) It was a shame since I had given the haul out operator the builders’ haul-out drawings. The drawings were more hurt than help since it turns out that Two Fish’s construction differs by about 1 foot. Those extra 12 inches of shaft length made all the difference. New boats are now coming with “straps here” stickers under the toe rail. Two Fish will also apply stickers.

The guys at the yard felt really bad. I said mistakes happen and no point in carrying a long face. Our friend Beth ordered us a new strut, but it would take two weeks to be forged. I quickly realized our poor luck was actually opening up some new chances for fun. But first a bit of work.

Haul Out from Two Fish on Vimeo.

Propellor Puzzle

When the boat has an issue, I go through a few stages of grief. First, annoyance, as I have no clue what to do next. When the dust settles, my brain starts to turn on as it is fun to work with Gail on solving the puzzle. I start unscrewing stuff and Gail starts reading. She ruminates on the topic while I attack the broken object. If the problem requires outside help, Gail will find the yard and I tend to work with the technician. We have learned volumes from workers. Since we are such bad students, we have to be in school year round. Ugh, summer school for Two Fish.

The propellor fix was going to be stressful since we would not be able to test the fix until the boat was back in the water. The boat’s splash was delayed 2 weeks by the strut, so we would have to be patient. I will not keep readers in suspense for 2 weeks. The cause of the the loss of forward gear was the Max Props. The blades are designed to rotate while sailing to create less drag. To accomplish this feat of engineering there are gears inside the propellor. According to the manual, the gears need to be greased every two years. However, after 10 months our grease had mostly washed out. Lesson learned, I will now add grease anytime I have access to clear waters. When adding grease it is important prevent an air bubble forming inside the gears. After greasing the propellors but while still out of the water, we noticed that our starboard propellor would not easily feather. The Max Prop technicians advocated bedding blows – a fancy way of saying hit the blades through their full range of motion and the air bubbles will burp out. It worked, and it was now time to test the boat.

We splashed in poor conditions for traversing that nasty chute. The current was strong and the well-intentioned docks guys lost control of the lines quickly. I should have warped the boat forward, but instead had the opportunity to perform a good test of the propellors. If they failed, we would be serving piling sandwich for lunch. The boat was squirrelly and I had a few shallow breaths, but we escaped without the sandwich. The propellors came through when I needed them. I would need their power a few more times later in the month. A representative from the yard was aboard for this short test sail and witnessed the exciting departure. In a stoic New England way he told me “good departure”.

- Good strut fresh out of the water, not too much growth

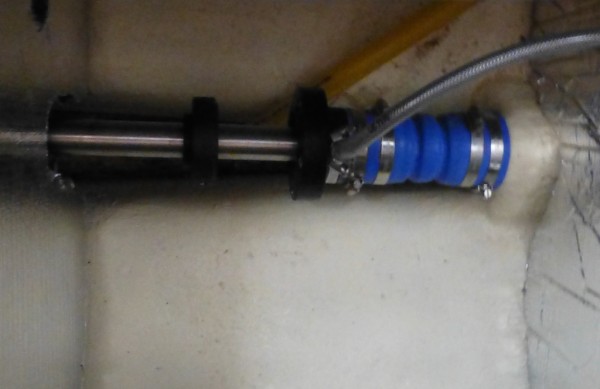

- Coupling, inside the boat holds the shaft to the transmission

- End of shaft, Propellor screws on, notice shaft key

- Shaft enters hull via cutlass bearing

- New strut

- A greased prop will ooze grease

Bottom Paint

We took advantage of being out of the water by doing some other necessary work on Two Fish. Bottom paints are supposed to stop organic growth on the hull. The best bottom paints are very toxic for the sea and are not legal in the United States. Other bottom paints are complex to apply and require good weather and the boat to be splashed within 48 hours of being painted. We decided to go the low tech route. We applied an ablative paint that is designed to rub off. I have a few swim suits that have bottom paint styling from rubbing into the hull. We applied 2 coats of Interlux Micron Extra with Biolux, rated by Practical Sailor magazine (consumer reports of the sea) as good but not excellent. Our first coat was blue and the second coat black so I will be able to tell when the outer coat has rubbed off.

Cleaning Her Underbits

The shafts, propellor and through-hull covers all need to be cleaned of super-barnacles. This species has evolved on Two Fish while travelling along two continents from cold salt water to warm brackish waters. A grinder is required to remove the super-barnacle. I was happy to see the hull was in great condition, despite my reduced diving since entering Maine’s chilly waters. We chose not to apply Speed Prop to protect the propellors from growth. We use the boat frequently and we plan on hauling out again soon.

Thru Hull Replacement

Ever since day one, a thru hull for the port head has leaked the tiniest amount. At first we blamed our friend Darren, but we later realized his conviction was as well thought out as the Salem witch trials. The leak was from the sea into the boat not from the head. Our thru hulls come in 3 pieces so pieces one and two can be serviced without haul out. Unluckily, Two Fish had a hairline crack in part three that allowed sea water to enter; this could only be fixed while out of the water. When we first discovered the problem, we decided to use underwater sealant to arrest this leak. It did an admirable job, but it is nice to have fixed the leak properly. Gail surprised the yard with her vast supply of spares. Yard guy: “It will take a week for that through hull to be delivered”. Gail: “No problem, I have one” Yard guy with a lowered jaw: “Really?”

Underwater Checks

I checked the rudders and also sent a photo to the builder to make sure they still looked problem-free. No issues to worry about -they are in great shape. Replaced 6 zincs. The cutlass bearing inside the strut was in good condition but the set screw was not in properly. We fixed that as well.

Shaft seals

Our shaft seals were in good condition but we replaced them 2 years early so that we could install a version that allows for easier emergency replacement. My recommendation for new boats is to ask for this upgrade on day one. Without that second black ring one would need to detach the shaft from the coupling and march it backwards. Not easy in a seaway. By the way, the coupling bolts should be checked with regularity. One friend had his seize up and another had them unscrew themselves.

Fuel polishing

We had a tiny bit of algae in our fuel filter and I decided to get ahead of this problem. We poured BioBor HF, highly rated by Practical Sailor, into the diesel tank. The yard then used their fuel polishing machine to remove the algae. Seems to have worked well. Might have been overkill, but better than clogged fuels lines when crossing an inlet. Despite our pleas, we were not allowed to race the polishing machine isn the town’s soapbox derby.

Cosmetics

We also cleaned the topsides and stainless, but the process of cleaning a boat is never over. Today I was still cleaning the teak (fake) with a ton of passion.

Free time

- Marleys has a great fish taco

- War of 1812

- Raid of Essex, British stole a bunch of ships and stores

- Beauty of wood shed

- Why are there so many Nonsuch in Essex?

4 Responses to Haul Out