Our greatest luxury and key comfort on Two Fish is fresh water. It is wonderful to be able to shower after ocean swims or before a long watch, to wash away salt from the deck, and, of course, to drink, make ice and clean dishes. Air conditioning, a fancy stereo, comfortable furniture and Internet are not nearly as important to me as an unlimited supply of fresh water. We have met remarkable cruisers that survive on only an eye dropper of water a day. To each is own.

Uses of water

I have not done a scientific analysis but here is my estimate of our water usage.

- Navy Shower

- Fresh Water Heads

- Washing Machine

Washing Machine: 7 gallons per load

Fresh water flush of watermaker (once per week): 5 gallons

Wash down deck: 5 gallons

Navy shower: 2 gallons

Washing dishes: 1.5 gallons per person per day

Head usage: 1 gallon per person per day

Drinking water: 0.5 gallon per person per day

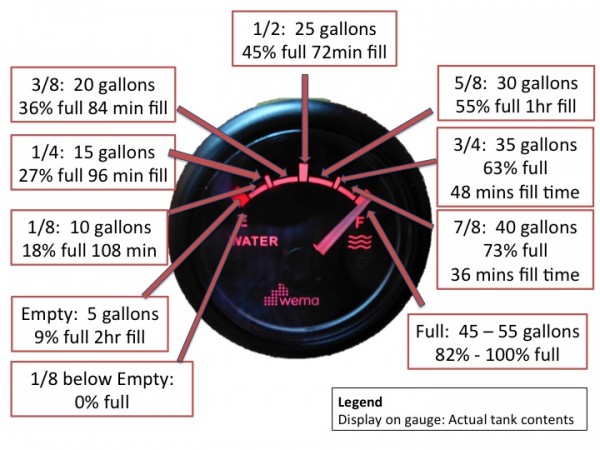

On a passage with four non-cruisers our consumption surged to almost 1 tank a day (55 gallons). This still holds its place as our most wasteful record. Our most frugal streak was with a similarly sized crew of cruisers – a tank lasted 1.5 weeks. When Gail and I are at anchor, a tank can last almost a week.

We have two 55 gallon tanks; when Two Fish was being built, we swapped fuel and water tanks to allow for more fuel to be carried on board.

Sources of water

Our tanks are predominantly filled by the watermaker, but we can also collect rain water or use the hose at a marina.

Rain Capture

Our boat has a huge hardtop with gulleys for water capture; these funnel to two stainless tubes. The tubes can be plumbed to lead to collapsible water jugs. Some owners insert an inline filter to catch sand. While at anchor, we use the rain water to wash scuba gear, wash vegetables bought from home gardens and wash the salt off the deck from bumpy passages. Typically, it takes an hour of rain to fill a 5 gallon jug. However, the Two Fish record (yes we keep records on all sorts of things) is 5 minutes and 12 seconds during a strong cloudburst in Brazil.

Dock Hose at a Marina

Dock water is plentiful but has a few drawbacks. Chemicals in dock water can pit the aluminum water tanks. We always ask twice if the water is drinkable (potable) when staying in a new place. Much of Brazil had water that locals suggested we avoid. My possibly unfounded fear in some countries is that the city water supply can get contaminated during a power outage at the treatment plant. In addition, older marinas may have old rusty pipes leading to the docks. Recently, we have been avoiding the hose and only using watermaker water to fill the tanks. When we do use marina water, we run it through an inline filter first.

Watermaker

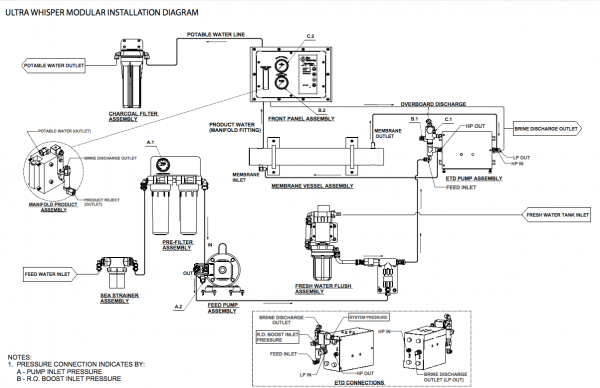

Our water maker is a Sea Recovery Ultra Whisper Modular 600, which produces 25 gallons per hour (95 liters). Converting sea water to fresh water can be accomplished via evaporation or by brute force. Most installed watermakers use brute force.

How to operate the watermaker

First, the unit needs power and water. Ours uses 110 volt power for the lift pump that draws the water from the ocean and 12 volt power for the control unit. On an Antares, the seacock must be open and the input/output valves set for water making NOT pickling. Get the input/output valves wrong and you will flood the boat. Fortunately, unless you are leaving your boat for a long time, these can be set correctly and left alone.

The control panel has a green “start” button to start the unit making water. This causes the lift pump to draw water and send it through the system. The system primes for about 40 seconds. Then, the ETD (energy transfer device) pump begins to squeak. Another 40 seconds and the water quality lamp will change from red to green. The manual advises that you may have to wait 30 minutes for the lamp to change color. This has never been the case for me. There is a red “stop” button to stop the unit. There are two other buttons, fresh water flush and fault clear. I stop the unit when the water tank gauge just reads full as I am not sure what would happen if I overfilled the water tanks via the watermaker hoses. If I press the red button only once, then in 90 minutes the unit will wash itself with fresh water. Many new owners think their fresh water flush (FWF) is not working because they do not wait 90 minutes. If you are patient, in 90 minutes you will begin to hear the pulsing of the 12 volt Fresh Water Flush pump and you will see water exiting via the brine port in the stern. We always give the watermaker a good clean after each usage. If you get excessively enthusiastic and press the stop button multiple times then the water maker will not execute the fresh water flush. Since the fresh water flush pump is a 12 volt motor, you do not need to have the genset on for the final step. Also, if the 12V power is left on, every week the watermaker will flush itself, a great way to have the membrane last without effort. The fresh water flush pump has a charcoal filter to protect the membrane from chlorine if city tap water is used for flushing. The fresh water flush uses about 5 gallons from the starboard tank, so make sure this tank has water. The fresh water flush pump makes a pulsing sound while running. If the pump seems more off than on then you need to replace the fresh water flush’s anti-chlorine filter.

- Thru hull, salt water enters here

- Thru hull, strainer, routing valve

- Under master bed, lift pump and FWF pump

- 110 volt lift pump

- Junction for fresh flush or sea water to water maker

- Pressure at filters

- ETD before/after pressures and flow rate

- ETD and Danfoss valve

- ETD open

- Membrane

- High pressure hose missing crimp

- Product water entering tank and tank selector

Behind the scenes at the watermaker

Raw sea water enters the boat via a thru hull and then passes through a strainer on its way to the water maker. The Antares thru hulls are in very smart locations. The Genset, water maker and engines will hardly ever be starved of water as the thru hulls are close to amidships. The cost of this comfort is a secondary raw cooling water pump for the Genset. The extra pump is worth it, to be able to make water in the ocean and not to have to wait until the boat is in a calm harbor, something that is necessary on some mass production cats. After the strainer, a football size lift pump, powered by 110 volts, pulls the water into the boat. Powering this pump requires the generator to be on. The strainer and lift pump are installed below the water line for automatic priming. The sea water now exits the master cabin and enters the rear locker where it passes through two filters to remove particles greater than 25 microns and then 5 microns. Initially, while the system is priming, the sea water takes a short cut and does not reach the membrane. 100% of the sea water exits the boat via the brine waste output located on the starboard stern. After one minute of priming, the control panel instructs the Danfoss valve to open. Danfoss valves are electronically controlled valves that open and close based on the watermaker’s control unit’s instructions. The now open valve allows the salt water to begin its conversion to fresh water. The water also passes through a UV lamp that kills microbes.

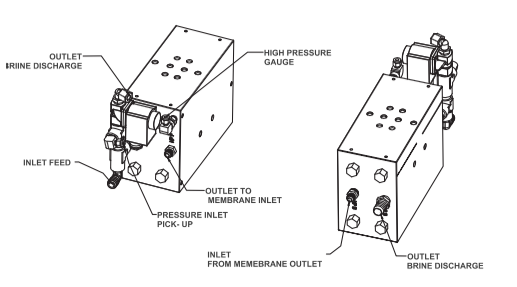

The sea water then enters the ETD, also known as a Clark pump, which pressurizes the water before entry into the membrane. The ETD uses the waste brine’s pressure to move the pistons, thus reducing the electrical load requirement of the unit. The ETD may be too complex a solution; other brands use a second pump. However, an ETD has fewer moving parts than a second pump.

The next stop for the now filtered sea water is the membrane, which is 1 meter long and has layers of material whose perforations are too small to allow the passage of salt crystals. The water that passes through to the center of the membrane is clear and good for drinking. Only 12% of the raw sea water is made into “product water” while the other 88% is sent over board as “brine”. These are two good terms to know when you start reading water maker manuals. The membrane should produce product water that has 99% of salt and other contaminants removed.

I do not make water in harbors or lagoons. We mostly make water while at sea to give the membrane the cleanest possible water and to extend the life of the filters. If you do make water in a place with lots of silt, then the filters will be exhausted early. But do not fret, as dirty filters are easy to change. However, oil can kill the expensive membrane, so one should avoid making water near the wreck of a super tanker.

The control unit does a few things behind the scenes. First, it ensures the pump pressure matches the needs of the system. Brackish water will perform differently than salty water. Second, the water maker tests the product for being drinkable. When the salinity tester deems that the water is clean, it opens another valve and allows the product water to enter the tank. There are isolating valves installed by Antares that route the product water to port, starboard or both tanks. Never have it routed to neither. I wish the system had a port to fill buckets. Someday I might add that, but in the interim I just unplug the quick connect hose.

After starting the unit it is worth checking the gauges for proper performance. For the Ultra Whisper 600, the product water output, which is read from the top of the silver float, should always read 25 gallons per hour when producing product. The main unit also displays the pressure on the low pressure and high pressure sides. The pressure reading will increase with colder or more saline water. These readings are taken just before and after the ETD. A proper reading for the low pressure side is 150 psi and 650 psi for the high pressure side. They will vary, depending on salinity and water temp. Finally, there is a gauge by the filters that should warn you of dirty filters. Some of the gauges suffer from chronic inaccuracy and need oiling or need to be reset. I write my gauge readings down frequently to see if something has changed. I have placed a label next to the gauges with the average expected reading.

The watermaker uses fewer than 10 amps @ 110 volts, so there is plenty of room while the genset is running to wash clothes, heat water, charge laptops and charge house batteries.

If you plan on leaving the boat for a month or two at a dock, the automatic fresh water flush will keep the membrane clean. Just make sure you have enough water in the starboard tank for the time you are gone. If you plan on hauling out for a season, the membrane requires pickling. The Antares watermaker is set up well for pickling; you can replace the sea water input with pickling agent from a bucket. Adjacent to the watermaker thru hull, there is a source selection valve that routes seawater to the water maker. Obviously, when water is being made the source must be the sea. If you wish to pickle the watermaker, the source must be set to hose. There is a hose in this locker that you can use to suck pickling agent out of a bucket. Bucket not included. This valve is operated in tandem with a second valve in the water maker locker that determines where the brine goes. It goes over board when producing water or back to the bucket when pickling. This is a very dangerous valve as accidentally routing brine into the boat could fill the locker with water very quickly. I always make sure, when running the watermaker, that the brine is going overboard. I have yet to pickle my watermaker; to do this, one needs a pressure release valve which I will install soon. I may spend the big bucks to buy a new membrane for our Pacific passage. Probably way too early, but I do appreciate tasty water.

- Extra water when machine was down

- Water Maker under repair

- Hammering the ETD

- Good to have spares of these

History

It has been over a year since we have had issues with the watermaker so it is a bit unfair to go back and complain now. Sea Recovery originally sold us a watermaker with a faulty ETD (energy transfer device) and a broken Danfoss valve. This led to a horror show of no water maker for our first 5,000 miles, in an area with limited fresh water. The ETD is a block of plastic with two pistons. Our ETD had poorly milled pistons and locked up when we used it. However, the lift pump would keep pumping water and the resulting water pressure would cause hoses to come off their barbs. I quickly had humor failure. The crew were great and never complained even though they had to ration water. We then took apart the ETD, a multi-hour process, and hammered the pistons back to the correct positions. The water maker then would work once, but not twice before blowing off another hose. We also had a few bad Danfoss valves. When the Danfoss valve was broken, I did a work around with a manual ball valve. Instead of electronically opening after a minute of priming I would manually open the valve. Bit of an ugly solution, but it worked okay until the pistons froze again. After running out of expletives, we gave up and waited for Sea Recovery to send us a new ETD. Like many marine companies, they claimed to have a global network but it is closer to global acquaintances, some of whom were not talking to them anymore. In short, we wasted lots of time in strange ports but now we know a bit more about the operation of a water maker. We also learned that fixing it yourself, now matter how clueless you are, is the fastest solution. The water maker has worked for over a year, since the repairs.

Conspiracy Theory

I tend to believe in free markets but in order for them to work consumers need to enforce the invisible hand. Plenty of watermaker buyers are clueless like me. I did not know the difference between a membrane and a pump, so I fell for marketing hype. Reverse osmosis water makers are old technology that is commoditized but the manufacturers wish to distinguish their products. They add features and great marketing slogans to lure the unknowing consumer. Then they make the spare parts slightly different shapes and sizes from off the shelf filters. This allows the watermaker manufacturer and dealer to lock the buyer in as a long term revenue stream. Sounds like my computer printer. Maybe my blog will educate a few future water maker buyers and the invisible hand will cause manufacturers to change their behavior?

Dream Installation

Watermakers often fail on boats. I do not think there is another brand that would outperform Sea Recovery. I would consider buying a “standard parts solution”. The Sea Recovery is very convenient with one button operation, automatic priming, automatic pressure control, automatic salinity sensor and flushing. But a “standard parts” solution would have fewer parts to break and replacement non-proprietary parts would be easier to find. I found this manufacturer on the web as an example. (http://www.cruiserowaterandpower.com/40_GPH_Water_Maker_2.html). With this model, one would have more switches and valves to operate; that might be annoying on a frequent use basis. I do not have experience with their products, but would research if we did this again.

My dream installation would be to have a second 12 volt watermaker. When on motoring passages, I could slowly top up the tanks without running the Genset and while on pure sailing passage I would fill the tanks while charging the batteries with the Genset. This set-up would offer a back-up, which would be comforting. For our Pacific crossing, I have decided to buy a portable 12 volt system that I will store in the sail locker in case old faithful decides to take a break at the beginning of our 3,000 mile leg. Two weeks ago, one of teams in the the Volvo ocean race had their watermaker stop working. For three weeks, the team will be manually pumping for eight hours a day from Brazil to Newport, Rhode Island. My arm hurts thinking about it.

While I am talking about my dream installation, I would like an hour meter to monitor the usage. This would not be useful in determining the time to change the filters since water quality can be a huge variable in filter life. The manual says change the filters when the unit stops working. I have not pushed it that far and change my filters too early. A remote starter panel might be nice but also adds another point of failure. I did add a taster port that allows for testing the product water. If the watermaker has not been used for more than two weeks, I reject the initial product water longer than the unit requires. I also have a handheld detector that measures parts per million of the product water. I use it, but I am not sure of its accuracy.

Another feature is to be able “plug into” a hose when in a Marina. The hose pressure replaces the need for a water pump and you do not have to fill your tanks. We do not have this feature, but before installing I would research how to avoid sinking the boat if the hose leaked.

I do enjoy the modular version on Two Fish as it makes service much easier. The compact version stuffs all the bits into a crowded space.

Golden Rules of Water Makers

1. No air in the system.

o Make sure the system has a good prime. Ensure good water flow at start up. If poor water flow, check for hose kinks or leaks on low pressure side.

2. Enough pressure from boost pump.

o Sea Recovery pump is matched to the unit’s need. Some home-made systems have lift pumps that are too weak or too strong.

o Ensure thru hull is not clogged and that it is underwater.

3. Clean filters

o Most common problem is clogged filters. We use only Sea Recovery filters to ensure the chairman’s child can go to private school.

4. Well-attached hoses

o There is significant pressure in the entire system. Check hose clamps and attachments to barbs. Ensure hose diameters match the barb.

o High pressure hoses will either be crimped or have a swagelok. Good to have a few swagelok spares. Ferrule ends can NOT be reused. Buy a few spares.

From Tank to Tap

Two selector taps exist under the floor boards on top of the starboard water tank to route the tank water from either the port or starboard tank to the boat’s water system. We only draw from one tank at a time; if a tap were to be left on, it would only empty one tank. We rotate the active tank from time to time so that the water is fresh.

After the tank selector, the water passes through a string filter. Sand, mostly oxidized aluminum from the tanks, will collect here. The water then flows to a variable speed water pump. When the pump senses the pressure in the water system has dropped, it starts pulling water from the water tank. If the pressure drops more, the pump increases its speed of pumping. When the tap is closed the pump eventually re-pressurizes the water system and the pump turns off. If a pipe were to come loose, the pump would keep pumping for eternity or until the motor burned out. In this case, the bilge would fill with fresh water until the bilge pump sent the water overboard. We often turn our fresh water pump off when leaving the boat overnight. We also track down the causes of unexpected water pump noises as they are clues to leaks in the system. The pump is fairly noisy, which sailors claim is good since you can hear when a tap is left open. I would prefer it if it were silent. They do not make these variable pumps anymore so we have a second pump as a spare. Our boat does not have an accumulator (pressurized fresh water reservoir).

After the pump, there is a charcoal filter to ensure tasty water. We change these filters every three months. If the water system has reduced pressure, then it is time to change the two filters. Fill a jug with some extra water. Turn off the water pump and open a tap to release pressure. Then fill the filter vessels with the extra water to assist in priming the water system. Without this help, the pump will struggle to reprime the system. The construction is very clever since spilled water lands in the bilge.

- String filters to remove sand

- Pre and post water maker filters

The fresh water from this point is pressurized and drinkable. There are several junctions as fresh water must feed 3 sinks, 3 showers, 2 heads, 1 deck wash down, 1 ice maker, 1 washing machine and 2 water heaters. The paths double as some devices require hot and cold water. The system is easy to maintain as all the connections are quick-connect plastic hoses. A leak can be fixed in no time, as long as you have spare tubing and a hose cutter.

The pipes are color coded (blue=cold, red=hot and teal=watermaker product). We also carry spare pipe connections and isolator valves. If you are trying to find a slow leak, the isolator valves allow you to shut off a portion of the system. The Quick brand water heaters are notorious for leaking from their overflow valves. We try to keep our bilge dry so that we can notice a leak in the water system or some other system. Other spots that might leak into the bilge are: Volvo raw water pump, shower sump, through hull (less likely), air conditioning, fridge/freezer condensation run-off, and shaft seal.

Conclusion

Jerry cans can be found on the decks of many cruising boats. Red for gas, Yellow for diesel and Blue for water. Some cruisers store a dozen empty water bottles that get filled when there is a clean water source. We are lucky and unlucky to not have to rely on dockside water. The water maker increases the comfort aboard immensely, but makes you dependent on a fragile machine. The right choice is personal, but, if you commit to technology, the Antares installation is very comfortable and well thought out.