Two Fish has a Furlex brand furler to manage both the genoa and the rarely used jib. Furling headsails allows a single person to manage the sail plan safely from the confines of the cockpit. No clipping in and roaming the decks in the middle of the night. Gail can easily shorten sail when a threatening storm is detected as an orange blob on the radar.

It is the current fashion for boats to hide the furling mechanism below decks, resulting in a modern look. However, I would consider this a liability on a blue water cruiser. I want a bullet-proof, easy to access furler.

A genoa furler is a bit like a toothbrush, we have used one for years, but, are we using it correctly? Well, here comes a lesson but without novicaine.

- When furling or reefing, head downwind. The lower apparent wind reduces loads and is kinder on the furling apparatus. A power winch is strong enough to furl while sailing hard on the wind, but at some point it will break your furler. The bearings will seize when you are entering a windy marina or at some other inconvenient time.

Inside the aluminium furler foil is a traditional headstay. This wire holds up the mast, not the aluminum foil. The foil spins around the hidden wire headstay. The lower drum has to be attached to this foil to allow it to rotate. There are two large bolts at the top of the lower drum that are screwed into the foil. It is worth tightening these bolts to avoid having the drum come free and lose foil rotation. We experienced the wander bolts; not so much fun, so now we carry spares if any bolts go swimming.

Inside the aluminium furler foil is a traditional headstay. This wire holds up the mast, not the aluminum foil. The foil spins around the hidden wire headstay. The lower drum has to be attached to this foil to allow it to rotate. There are two large bolts at the top of the lower drum that are screwed into the foil. It is worth tightening these bolts to avoid having the drum come free and lose foil rotation. We experienced the wander bolts; not so much fun, so now we carry spares if any bolts go swimming.

- Another bolt to check is hidden under the drum. This bolt and plastic plate hold the entire drum in place. If this bolt is loose the furling line will come out but the drum will not spin. This bolt is shy and will only come loose on a dark stormy night so check it while the weather is fair.

- A sail can be furled clockwise or counter-clockwise but only one direction will have the UV protection showing. Try the wrong way and your sail will look like a barber shop poll. The foil has two tracks. The manual suggests using the track opposite the sail’s first contact on the foil. It is not going to materially impact the furling if fed via the wrong track.

- When the sail is stowed, I like to have five wraps around the drum. Too few wraps and when you stow the sail under load you will run out of furling line. We have avoided that horror show. Too many wraps and the jib will not fully deploy as the drum gets too full of line. I recently upgraded the furling line to a narrower 10 mm spectra so I may be able to carry more wraps and should have less friction in the furling system.

- This should be rule #1. When furling and the winch sounds odd, STOP. Really STOP. Go look at sail, drum, furling line, sheet, halyard at the head and anything else. Then go look a second time. Your ears are not wrong; something needs to be fixed. You can save time by holding down the electric winch button and after a few seconds you will hear something break. That later technique is more expensive, but is popular. Power winches are evil. A halyard around the forestay coupled with a power winch can destroy the foil and place huge stress on the forestay. Now you seem very interested in knowing the causes of a wrapped halyard. A loose halyard, poor greasing of the top drum or using a smaller sail without a pennant all can cause halyard wrap.

- The distance from the halyard exiting the mast to the rotating drum should be less than 15 inches. This allows the halyard to be sloped towards the foil. If a smaller headsail is hoisted, the distance could be several feet and the foil and halyard will be almost parallel. This increases the chance of halyard wrap. To avoid this, attach a pennant to the sail. I prefer placing the pennant at the foot.

- When stowing the sail, make the wraps neat so wind can not enter but not so tight that the sail is getting crushed. However, when reefing the wraps should be tight to have a smaller and higher performance luff.

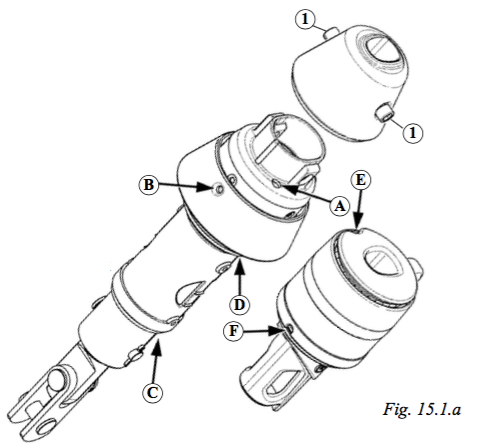

- The following diagram from the manual shows grease points. To do this properly the lower furler must be taken apart. Four screws detach the feeder from the drum. One bolt from the bottom plate. Wash with fresh water and use a brush on the four sets of ball bearings. Then use the Furlex provided grease. Reading the manual somewhere in this process may also be a good idea, as some furlers with durlon ball bearings hate grease. According to a few riggers, 90% of furlex failures are related to boats that have not greased either drum in 10 years. The top drum tends to fail first.

- Outer drum from in front

- Outer drum from above

- Plate that holds drum in place

- Bearings exposed post drum

- Wow, who would have thought that there is so much to discuss on a very basic system? Halyard tension is used to reduce the draft on the sail. Only adjust the halyard with the sail fully deployed. (You knew that!) The trap with a catamaran is that there is a limit to the halyard tension. Since a catamaran lacks a back stay it is possible to add too much halyard.

- To deploy the genoa should not require a herculean effort. Washing the line organizers or ensuring no twist is in the furling line could solve this problem.

A well-maintained furler and a thorough understanding of its mechanisms can reduce the number of unexpected issues and make a dark and stormy night less scary.

One Response to Roller Furler – How to keep it rolling